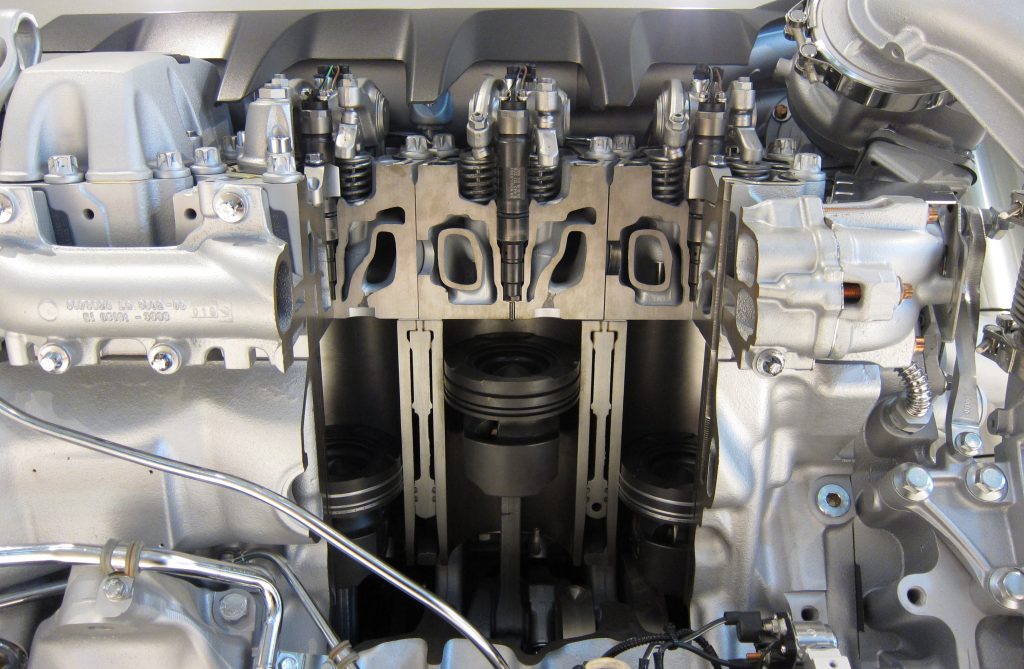

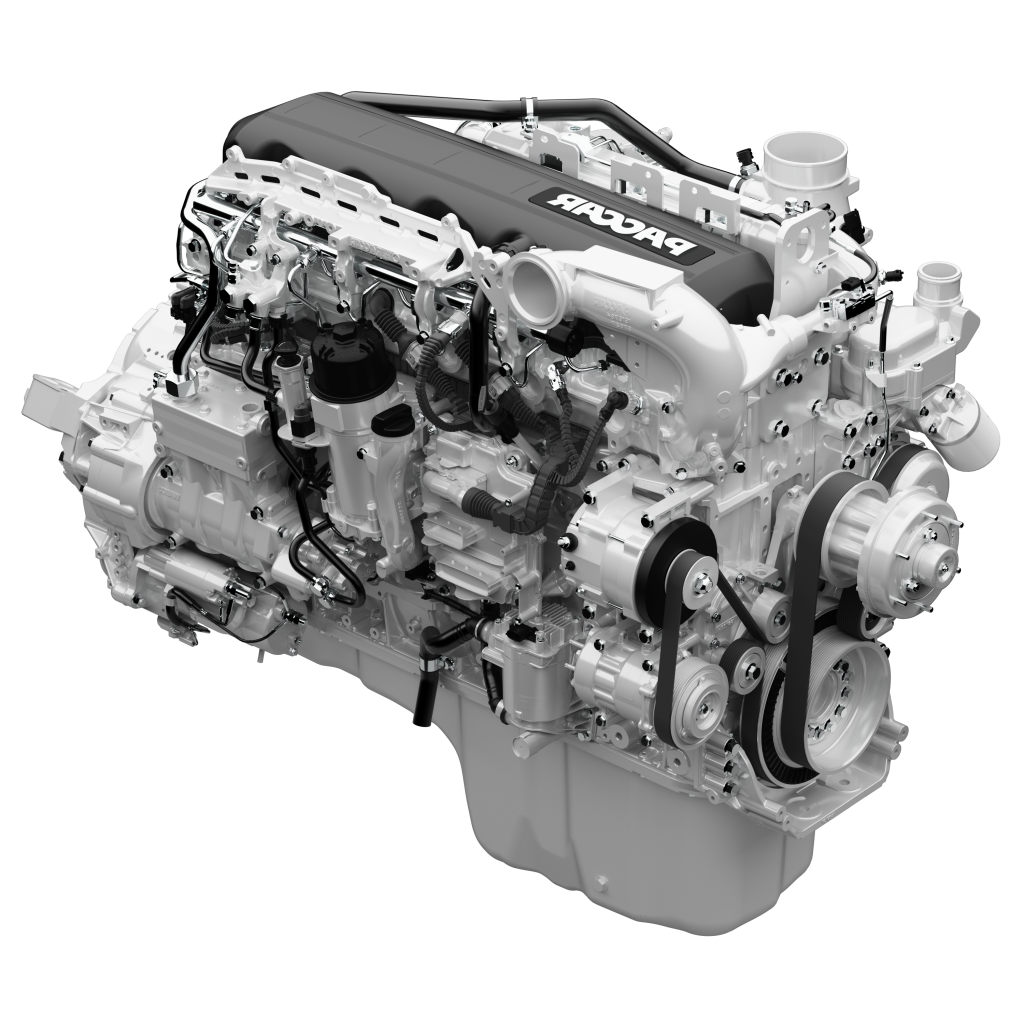

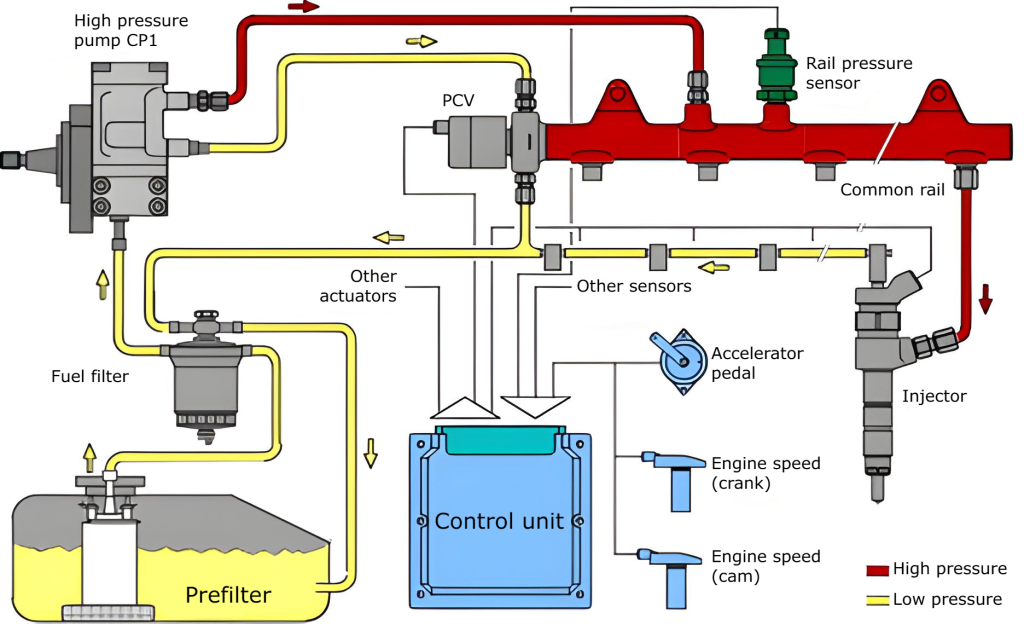

The fuel system can be divided into low pressure & high pressure circuits. Low pressure components include the fuel tank, fuel supply pump and fuel filters. The high pressure side components include the high pressure pump, accumulator, sensors, pressure valves and the fuel injector. A number of injection nozzle designs and different actuation methods have been developed for use with different types of fuel injection systems.

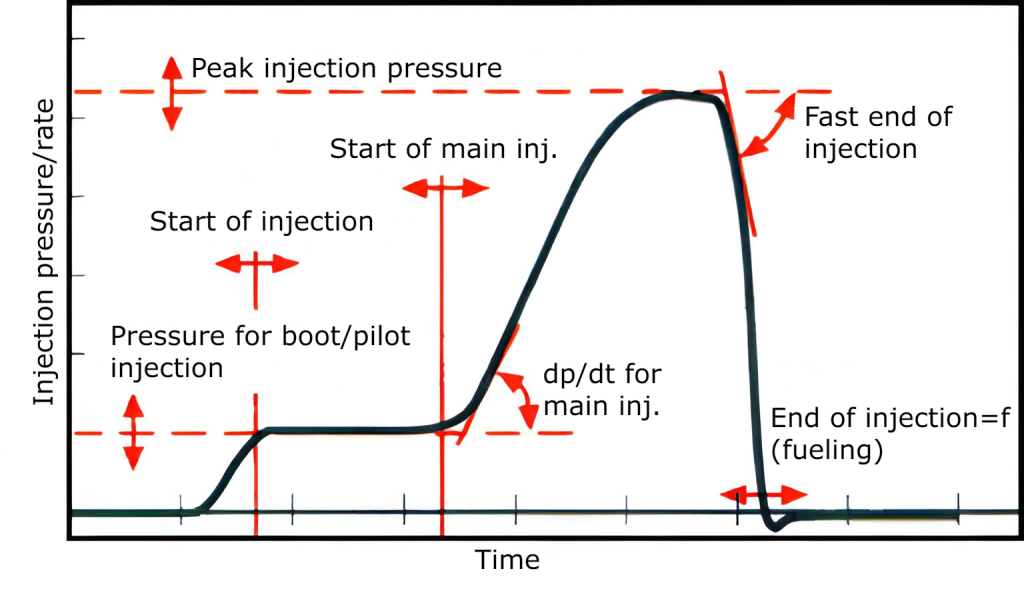

Fuel injection systems utilize advanced electronics via ECM, modules, sensors & circuits to allow the injection event to occur at the precise moment for optimum fuel burn. Components are built to extremely close tolerances to allow the system to maintain accurate metering and injection within crucial timing angles for precise engine management.

Ensuring the fuel atomizes into the smallest possible fuel particles is a primary design objective for the diesel injection system. Microscopic droplets ensure that ALL the fuel is vaporized and burned during the combustion process-this ensures optimum power & lowest possible emissions out the exhaust stream.